Bagmax Bubble Mailer Making Machine

Features

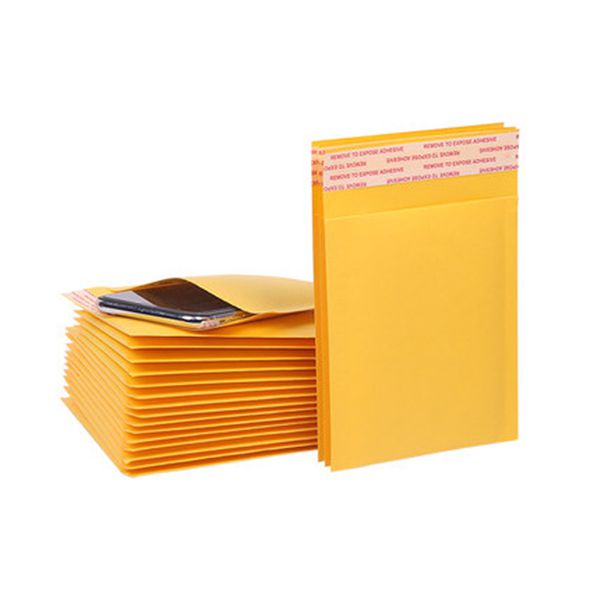

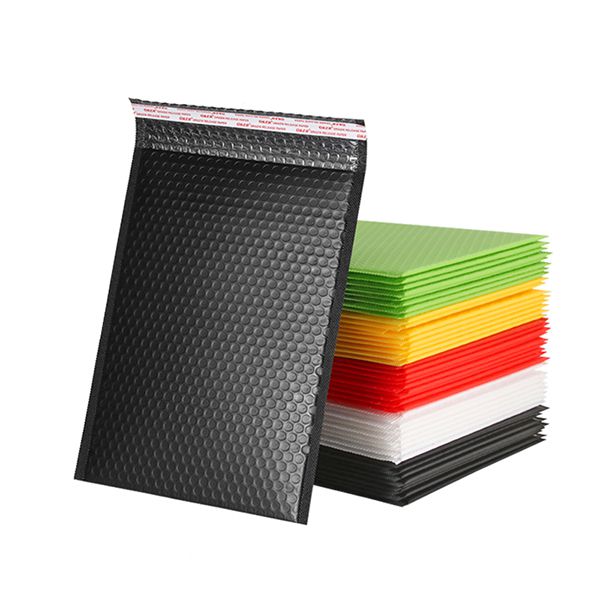

- Can produce kraft bubble mailer, poly bubble mailer and metallic bubble mailer;

- Adopting high-precision motion control and reliable transmission system, ensuring smooth operation;

- Output up to 300 bags per minute;

- Advanced mechanical design saves your maintenance cost;

- Easy to operate, user can operate the equipment with only one-hour training;

Details

Specifications

| Model | PTZD-C-800 |

| Material | PE coated kraft paper, 2-layer air bubble film; 4-layer aluminum laminated air bubble film; 4-layer PE laminated air bubble film |

| Bag length (mm) | 750 |

| Bag width (mm) | < 1000 |

| Output (bags/min) | 30-360 (depending on bag size) |

| Operation power (kW) | 30 |

| Dimension (L×W×H) (m) | 20×2.6×3.2 |

| Weight (kg) | 4000 |

Get in Touch

Protective packaging is no mystery in playing the most important role across many industries due to its function in keeping fragile or sensitive items safe from damages. In response to the market needs, since the foundation in 1992, Pansatec has been investing on the innovation of plastic film machine and plastic bag converting machine for applications of inflatable packaging and air-cushion packaging. Our engineers have developed a wide variety of customized bubble film machines such as bubble film extrusion lines equipped with either single screw extruder or twin screw extruder, plastic film laminating machine, plastic bag making machine, poly mailer machine, and more inflatable packaging equipment to produce high quality bubble film bags, air cushion films, bubble padded mailers, bottle protectors, inflatable cushioning materials and radiant barrier films, which can offer excellent protection or reflective insulation for customer individual needs.